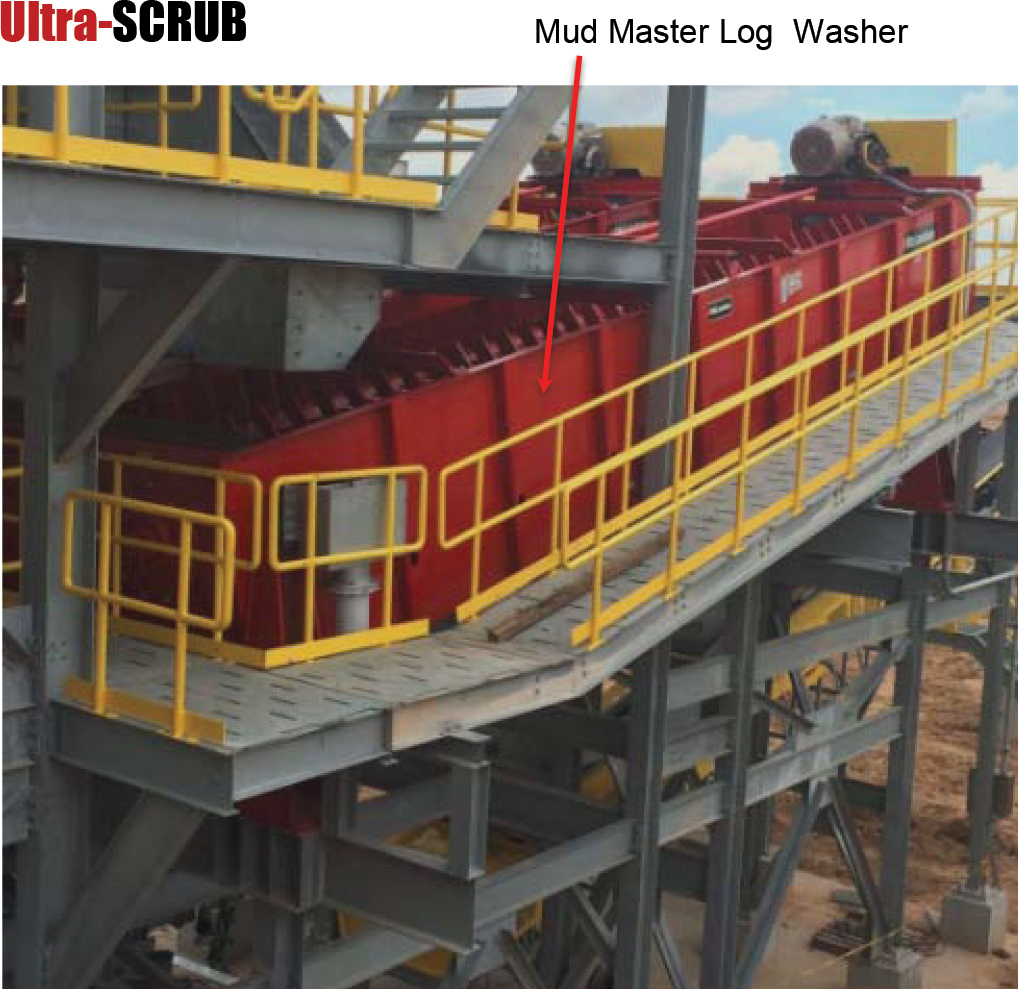

McLanahan UltraSCRUB

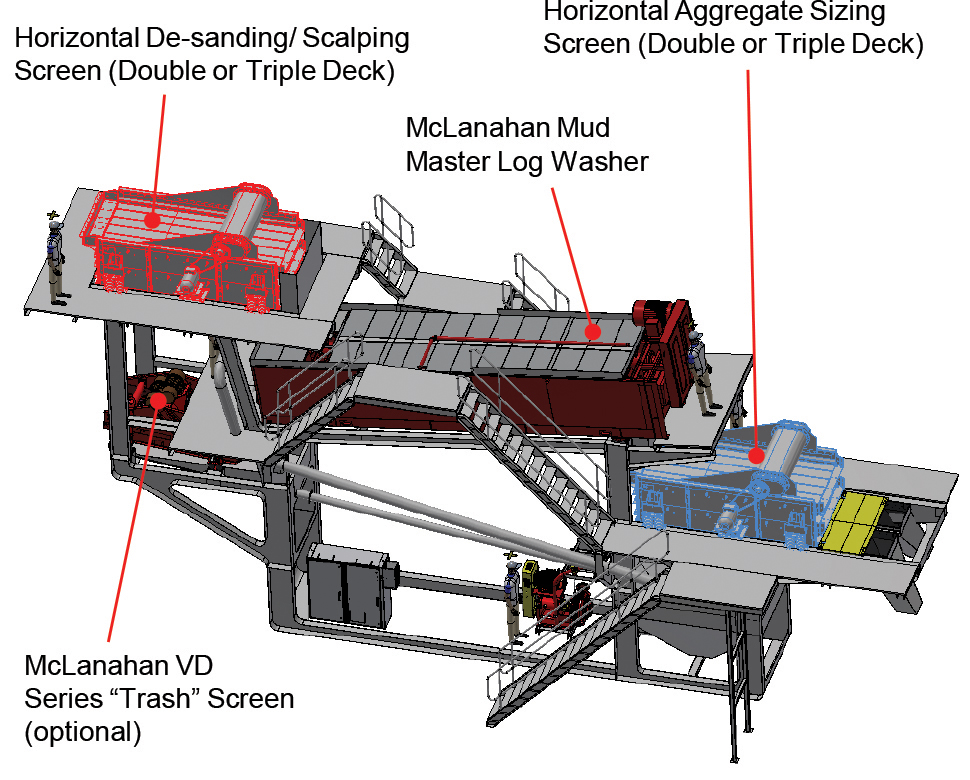

Capable of removing adhered and difficult-to-remove materials such as high plasticity clays from otherwise valuable aggregate, the McLanahan UltraSCRUB Modular Scrubbing Systems provide a flexible attritioning/scrubbing and final sizing option for otherwise waste material.

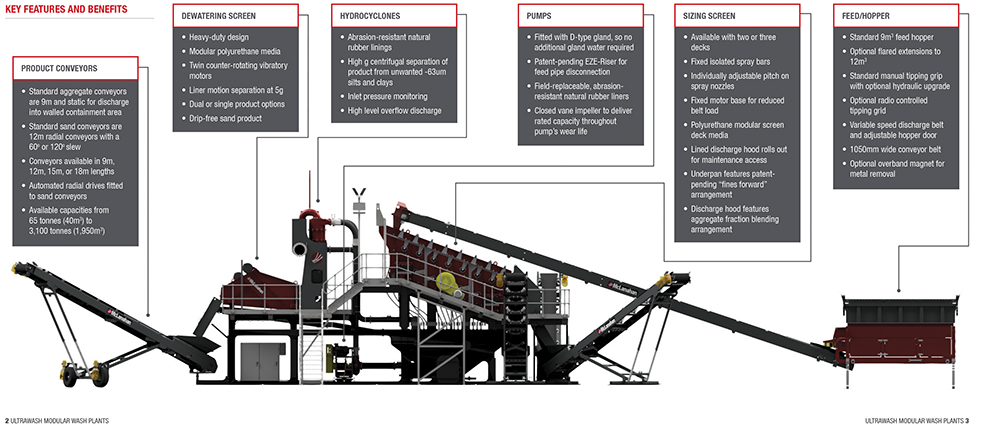

Arriving on-site in containerized modules, producers will benefit from the shorter lead times, quick set-up and ease of transportation offered by the UltraSCRUB.

When combined with other modules from McLanahan’s modular equipment line – such as the UltraCRUSH, UltraSCREEN and UltraWASH – producers can create an entire plant to process aggregates that had previously been classified as waste.

Features & benefits:

- Material and water are introduced in the feed end of the unit.

- Paddles provide scrubbing and agitation

- This scrubbing along with rising current water breaks down and washes off light coatings and light clays

- Organics removal (i.e. wood, leaves, etc.)

- The “cleaned” product is then conveyed to the discharge end of the box

- A rinse screen typically follows the Log Washer 2, 3 or 4 Aggregate Products

- With desanding screen (optional), log washer, horizontal rinsing screen, trash screen (optional) sand transfer sump and pump, transfer/ product conveyors.

The Ultra-SCRUB range comprises:

LW3625 – up to 100/200mtph

LW3830 – up to 200/400mtph