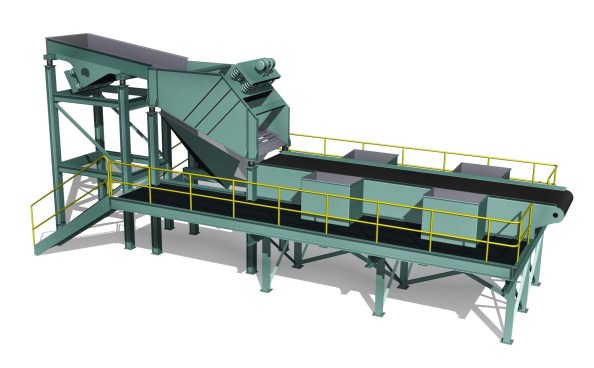

Thor Telescopic Cable Mast Conveyor

Thor Global has applied telescopic technology to a traditional cable mast system that has been successful in stockpiling applications for decades. Thor Towerstacker is a scalable product that has been engineered to perfection using a rail system configuration that is capable of handling the higher pressures of a larger machine.

Pile Higher – Enlarged structural design enables you to stockpile material in excess of 350,000 tons and 4000 STPH.

Easy Maintenance – Conveyor can be lowered all the way to the ground to provide easy access for maintenance.

Greater Clearance – No head or tail undercarriage provides greater clearance under the conveyor.